Preserving what matters

Corbion unleashes the power of algae fermentation to preserve the planet's limited resources. Our sustainable solutions help customers advance diets and reduce pressure on marine resources without impacting the carbon footprint.

We're the first and only company to use industrial-scale fermentation to create sustainable nutrition from algae – learn how our technology works and how it meets different market needs here.

Omega-3 fatty acids growing demand

As the global population continues to grow, so do the food production challenges. One such challenge is the supply of long-chain polyunsaturated omega-3 fatty acids such as DHA (docosahexaenoic acid) and EPA (eicosapentaenoic acid).

Long-chain polyunsaturated omega-3 fatty acids are essential nutrients. They are synthesized by humans and most animal species at low levels and play a crucial role in human health, helping to maintain heart, brain, and eye health.¹ They may also help lower the risk of heart disease.²

As in humans, Long-chain omega-3s are essential for animal nutrition, promoting health during growth, development, and reproduction.

To meet daily nutritional needs, we need to add these critical ingredients to diets. Thus far, most long-chain omega-3s in the human and animal diets come from fish oil and other marine resources (salmon, and other oily fish, for example).³

1 Cleveland Clinic, Omega 3 Fatty Acids

2 FDA qualified health claim

3 Cleveland Clinic, Omega 3 Fatty Acids

Today the world faces a significant shortfall in the supply of long-chain polyunsaturated omega-3 fatty acids and a race to develop more sustainable ways of obtaining the nutrient, reducing pressure on marine natural resources.

As a result, the growing demand for sustainable omega-3 fatty acids is a pressing challenge.

Why Algae?

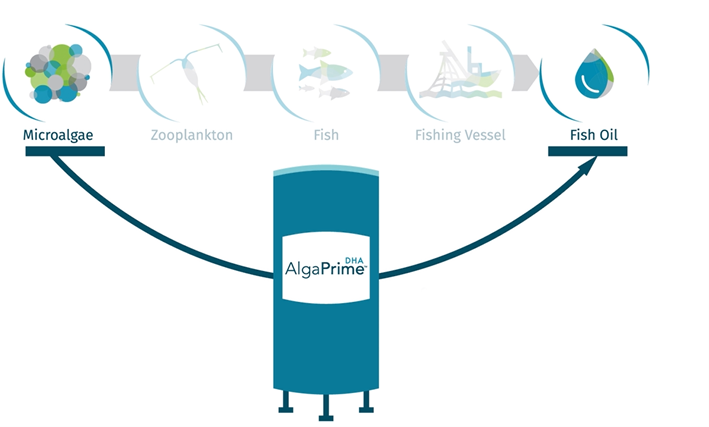

In nature, marine microalgae are at the base of the food chain and the original source of omega-3 fatty acids that later accumulate in these fish. To meet the production challenges and growing demand of Omega-3s, microalgae fermentation plays a strategic role as we access its naturally original source.

We're pioneering a new way to create Omega-3s that are sustainable, affordable, and at scale.

Our proprietary fermentation process transforms microalgae into high-quality and health-promoting Omega-3 products, taking the “middle fish out”.

Our company has ground-breaking R&D in algae strain development and fermentation excellence. Our research team has screened thousands of algae strains to identify the most productive, efficient, palatable, and nutritious algae strains.

Sustainable production

Our production facility was designed to embody sustainability principles in creating microalgae-based products with low carbon, water, and land use impacts. Our microalgae are grown in closed fermentation tanks where they transform renewable, sustainable, plant-sourced sugars into algae in a matter of days. Our facility is situated among the sugar cane fields next door to a sugar cane mill.

Compared to other sugar sources like corn and wheat, the sugar cane we use to grow algae serves as one of the world's most productive sugar sources. The sugar cane waste provides a renewable source of energy that fully powers the sugar mill and our algae ingredients facility.

To measure the environmental impacts of omega-3s produced by algae, a comprehensive Life Cycle Assessment (LCA), assessing six impact categories, was conducted for our omega-3 products, in powder and liquid suspension formats.

The deep research experience is coupled with a sustainability mindset and world-class facilities and production expertise, providing an efficient, clean and sustainable source of long-chain omega-3s called AlgaPrime™ DHA.

AlgaPrime™ DHA delivers sustainable solutions to help our customers meet this challenge, reducing dependency on fish oil, and reducing pressure on marine resources, without impacting the carbon footprint, while promoting human, animal, and ocean health.

Click here for more information.